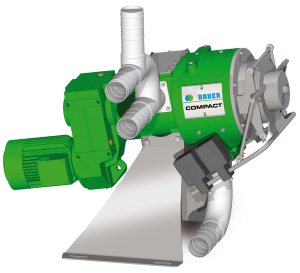

Bauer Separation technology

Strong output and optimum dry matter content

are the characteristics of BAUER Separators. Their long durability lead back to many years of experience, perfect technical design and the use of high quality material. This makes us the technological leader in this field.

Based on our quality assurance system ISO9001 and constant development of all our components, Bauer manufactures products of only the highest standards.

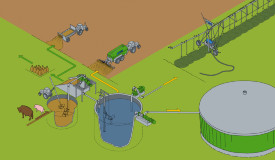

The BAUER SEPARATOR converts manure into a valuable fertilizer

- Fully-automatic separation – that means splitting up slurry into a liquid and a solid fraction – offers great advantages.

- The thin slurry remaining can be distributed any time without any sophisticated homogenizing techniques.

- The odorless solid fraction is easy to store without any problems

Separator Models

liquid from solid nutrients.

Why Separate