Pumping technology

An essential factor in order for the complete system to function is the transportation of fluid mediums on agricultural farms, but also in the industrial field. The gear and pedestal pumps with special and powerful cutting units are also suitable for conveying slurry or fluids with long fibres and a solids content up to 12%.

- efficiency

- feeding of separators

- high recognition value

- multi –drive, many fields of application

- easy maintenance

Submersible pumps

Bauers pump series impresses with outstanding performance, many fields of application and longevity.

- outstanding cutting performance

- high-quality chrome steel cutting unit

- efficiency class IE2

- temperature monitoring for use in biogas plants

- additional security through leakage sensor (optional)

Bauer SM & SX Series Pumps

MAGNUM CSP/ESP

MAGNUM ESPH/ CSPH

Delivered without plug!

- submersible motor pump with adjustable cutting device (CSP)

- spiral housing and suction bell made of cast iron

- CSPH: Impeller and cutting disc made of chrome steel

- ESPH: Impeller made of spheroidal cast GGG60

- pump shaft made of stainless steel with angular ball bearing

- three phase current – submersible motor 4-polar for 400/690V/50Hz / IP 68 with 8m cable 12G x 2,5² 1m cable protective tube and strain relief

- sealing on motor end: mechanical seal in oil bath

- sealing on pump end: closed and stainless steel mechanical seal

- motor temperature class H, with triple PTC resistor 180° C, for thermic winding protection

- medium temperature up to 65° C

- leakage sensor extends into oil reservoir (additional motor protection )

- motor and cable strand on junction plate, strand of leak oil sensor and PTC on ceramic clamp interconnected in a terminal box casted in casting compound

- motor protection guaranteed by the original BAUER control system (accessory) with installed thermistor release relay for PTC resistors and overcurrent relay, as well as electronic monitoring system for leakage sensor

Leaflet PDF MAGNUM LP/S

MAGNUM S

- cast iron pump volute

- cutting bell with large, ribbed intake

- cutting impeller and cutting bell of spheroidal graphite cast iron with hardened cutting edges

- pump shaft of stainless steel with angular ball bearings and double, silicon carbide mechanical seal running in oil bath

- three-phase submersible motor, four pole for 400 V / 50 Hz / IP 68 – 1450 RPM

- motor housing of grey cast iron, motor winding with 3 PTC thermistor detectors, insulation class F

- heavy-duty rubber cable 8 m ( 12×2,5), screwed cable joint with strain relief

- motor protection is guaranteed only with original BAUER control unit (accessory) with built-in thermal tripping relay for PTC thermistor detectors and overcurrent relay

- delivered without plug

Leaflet PDF

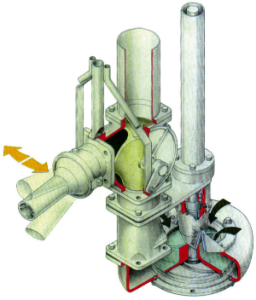

Pumping and Chopping

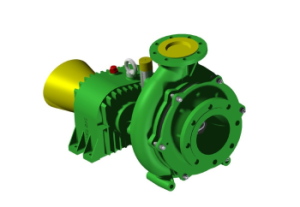

Top quality and enormous capacity are Bauers principle for both series: the MAGNUM SX (centrifugal pump) and Helix Drive (eccentric screw pump)

- can handle up to 12% solids

- largely insensitive to foreign objects

- efficient and economical

- easy maintenance

- Multi-Drive- different driving options

- low operating costs

Bauer CSP/ESP/S Series Pumps

MAGNUM SM 540

Standard Extent of Supply SM 540

- tractor gear pump with adjustable cutter flange

- spiral housing of grey cast iron

- suction flange with ribbed inlet

- thick matter impeller of spheroidal graphite iron with hardened cutting edges

- cutting plate and wear plate of spheroidal graphite iron

- spur gearing with case-hardened helical angular teeth

- case-hardened pump shaft w. helical angular teeth and with angular contact ball bearings and cylindrical roller bearings

- mechanical seal (silicium carbide) with oil reservoir

- rinsing connection with Geka coupling

- suction/Delivery connection DN 150/100

Leaflet PDF MAGNUM SX

Product Range MAGNUM SX

- SX 1000 with heavy-duty gearbox as tractor pump

- SX 2000 with heavy-duty gearbox for Diesel engines

- SX 2600 with pedestal mount for electric drive motors

Technical features

- Pump housing: of special design, ensures unobstructed delivery of viscous liquids

- Cutting blades: easily adjustable to maintain the ideal cutting gap, draw cut, high-grade casting

- Suction flange: ensures enormous suction capacity, prevents turbulence

- Protection plates: For a long service life

- Shaft sealing: Of industrial standard, double-acting mechanical seal with oil reservoir

- Pump shaft and bearing: Amply dimensioned

- Gearbox: Of compact industrial design

- Automatic pressure regulation: (optional equipment) For changing conditions of use

Mounting variants

- SX 1000 on a pump trolley

- SX 1000 on a hoisting frame for three-point linkage

- SX 2000 on a trailer with diesel engine

- SX 2000 on a mobile unit with diesel engine

- SX 2600 on a base plate with electric drive motor

Leaflet PDF